Supercharge Your Shipping. Grow Your eCommerce Business.

The Cheapest Shipping Rates, Guaranteed

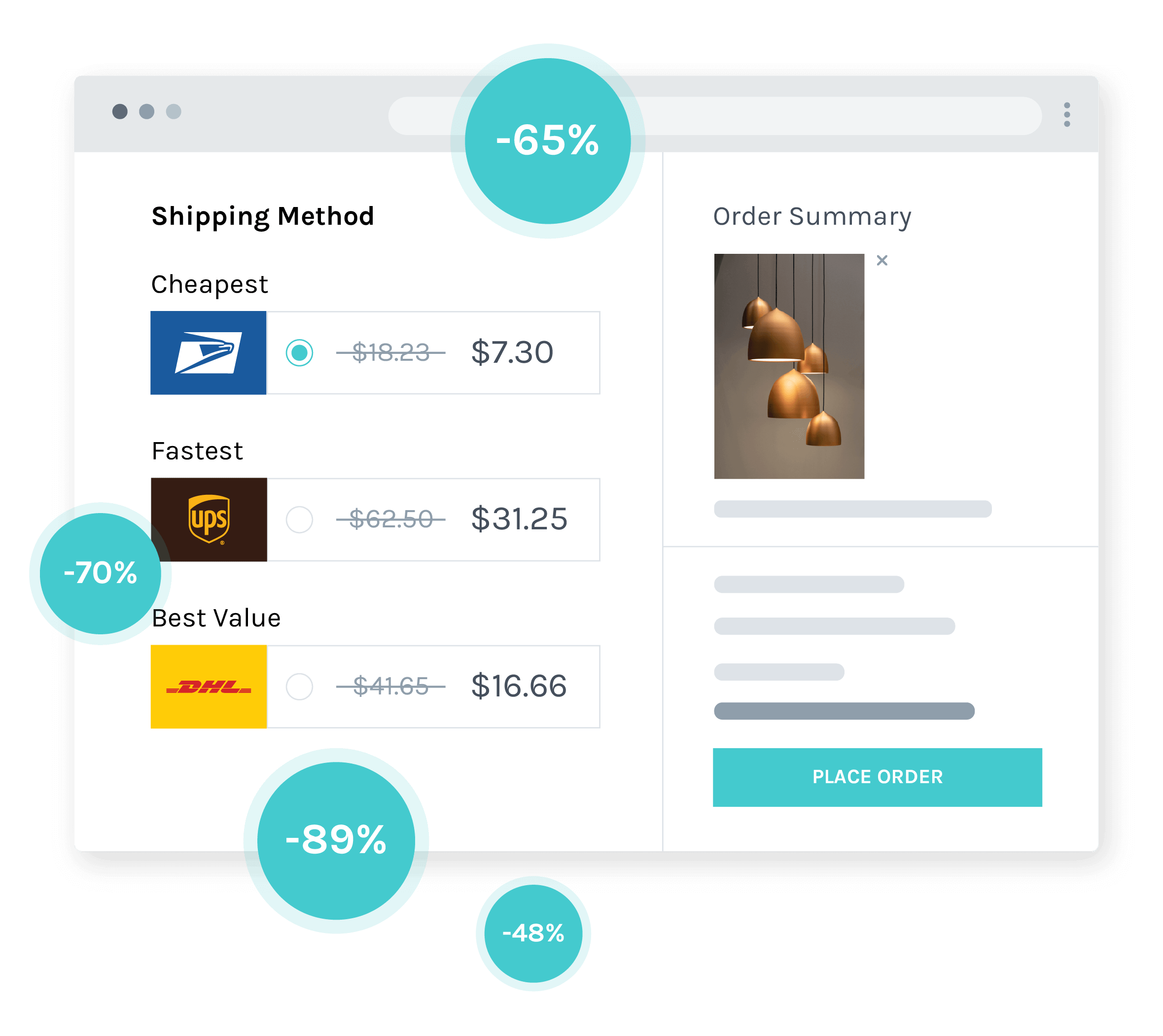

Stop overpaying for shipping. Our rates remain unbeaten and are available to everybody. See how you can save up to 89% on top couriers. With 250+ courier services from USPS, UPS, DHL and more, we have the right courier for your needs. See available couriers and shipping rates.

Unlock Global Growth

Boost revenue by selling worldwide, seamlessly. Cargo does the hard work by integrating with leading international couriers, calculating tax and duty costs and preparing the right paperwork for smooth customs clearance and delivery. Learn how Cargo handles customs clearance.

Improve Your Store. No Coding Necessary.

Increase checkout conversion rates with dynamic rates at checkout. Show the best selection of couriers, in addition to delivery times and fully landed costs. Learn how checkout drives conversions. Cargo is seamlessly integrated with leading eCommerce platforms and marketplaces. You can manage all your shipments without writing a single line of code. See our integrated platforms.

Never Waste Time on Shipping Again

One tool to manage and automate all your shipping needs. Compare shipping quotes, generate labels, schedule pickups, and monitor finances through our intuitive cloud-based shipping software. Explore our shipping software.

Access Our Network of Global Warehouses

Improving transit times, lowering shipping costs, and reducing tariff exposure has never been easier than with our global network of 3PL partners. Our shipping consultants will tailor a fulfillment strategy perfect for your business. Learn more about our fulfillment network.

Delight Your Customers

Exceed your customer’s expectations with a curated delivery experience. Keep your customers informed with shipment tracking pages and emails that match your branding, and customized packing slips for a personal touch. Learn how to brand your delivery experience.

Cargo is Built for Your Business

We help all types of businesses manage their shipping needs.

Whether you're just starting out or gaining some traction, our shipping solution is built to meet the needs of brands and customers alike.

So, you've launched a successful crowdfunding campaign. Now what? We have a turnkey solution for campaigns of all sizes. See our crowdfunding approach.

Do you have specific fulfillment systems and needs? Our intuitive shipping API lets you manage your flows within your own system.

You’re In Good Hands

We're happy when our customers are happy. We pride ourselves on going above and beyond.

-

Get the Help You Need, 24/7

We work around the clock to get your shipments to the right place at the right time. Our support center is second-to-none.

-

Become a Shipping Expert

Our resource library has everything you've ever wanted to know about shipping.

Start Shipping in Minutes

You can try us for free. Everyone loves free.

Already at scale? Our shipping and logistics experts can build the perfect global logistics setup for your needs.